We provide 100% Survey, with 0 volume averaging.

ISO-Pacific offers the most sensitive, reliable, and efficient soil-sorting technology available. ISO’s patented S3 design and operational characteristics offer our customers the following benefits, none of which are found in total in any other system or company:

- Maximum mechanical reliability

- Unparalleled quality control features

- Unmatched field detection sensitivity

- Rapid calibration time

- Customer-Friendly data reporting

- Mobilization/demobilization costs half of current industry

- Ability to sort a variety of soils and materials

Sortable Materials

- Soil types, include but are not limited to; wet clay, gravel, sand, ash rubble, construction debris, etc.

- Other materials, including but not limited to; plant materials, metals, brick, foodstuffs, NORM scales, and more.

The benefits of nearly three decades of soil sorting experience and lessons learned are built into our machines. The S3 is designed to handle a wide variety of soil types and their problem characteristics, including high moisture content, high plasticity, poor gradation, physical interference from organic matter and tramp debris, and many other phenomena associated with soil sorting.

Demonstration Video

S3 Technology

ISO entered this industry with its Soil Sorting System (S3), a revolutionary improvement in the technology used to provide volume reduction for contaminated sites. The patented S3 is an automated system that detects and segregates contamination from otherwise clean soil. The use of the S3 will reduce schedule time, lower transport and disposal costs, and facilitate stakeholder confidence due to the extensive data collection.

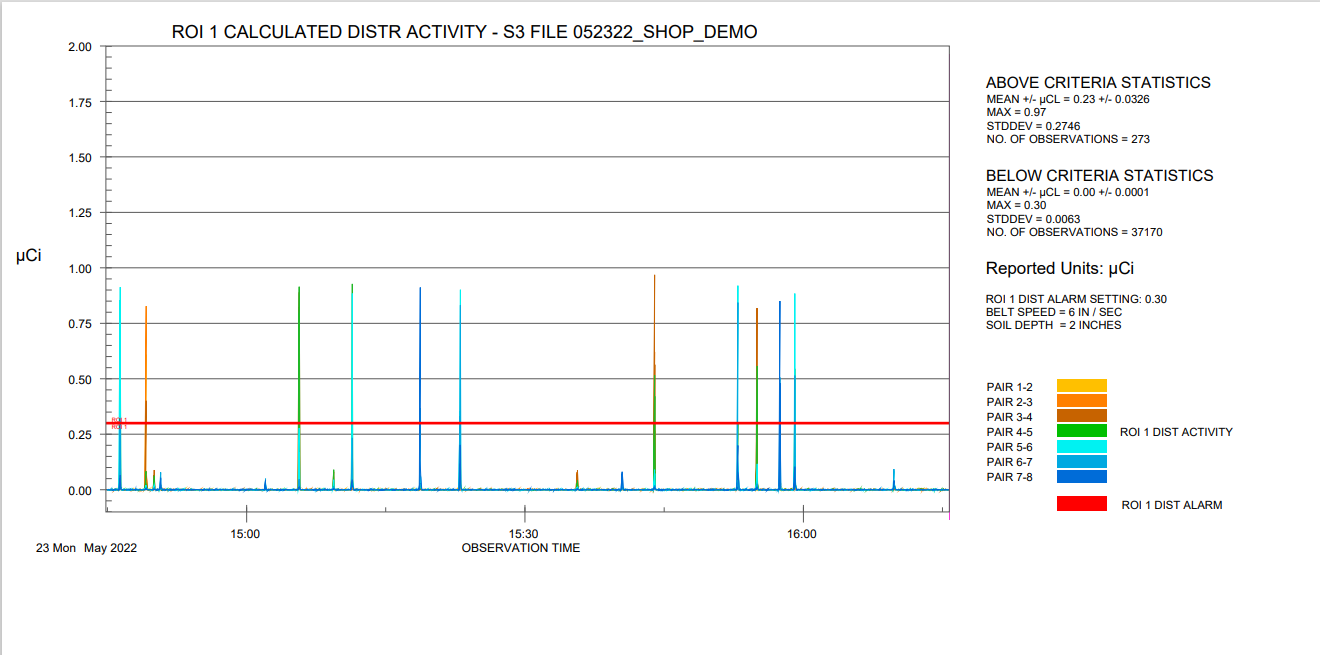

The ISO-Pacific S3 utilizes a 72″ wide assay belt, accommodating a layer of soil up to four inches in depth. With a fixed speed of 6 in/sec, production volumes range from 40 to 100 cubic yards per hour. The target material is transported on a flat conveyor belt in a uniform flat layer below an array of detectors where depth and density are matched to the photon emission and attenuation characteristics of the contaminant of concern.

100% coverage means that the overlapping field-of-view of the scanning instruments has covered the entire soil volume and provides a high level of confidence that all areas of elevated activity are identified. Scanning the entire volume of material can give peace of mind, knowing all the above criteria material has been extracted. A 100% coverage S3 scan is less expensive than the potentially costly alternative of finding areas of elevated activity later in the remediation efforts.

A hallmark of ISO-Pacific’s platform creation strategy is customization. High-performance detectors are specifically chosen and placed in array formats tailor-made to our client’s needs. Previous arrays have included options such as specially-shaped tungsten wells for each detector; added “shadow” shield flat plates which help to attenuate any photon emissions reaching detectors from the ground below the S3; and methods to ensure the array is temperature-controlled and monitored for humidity. ISO develops detection arrays with the project conditions in mind to ensure client savings and no contaminant is missed.

The S3 adheres to all MARSSIM-prescribed quality assurance and quality control directives for a detection system. Calibration is performed on-site, upon arrival, using the counter manufacturer’s automated calibration software. The S3 cannot operate until the S3 operators have satisfied the software’s pre-start calibration checklist. Human errors and bias have been removed from the equation.

Patent No. 9,457,382

Reduce Exposure

Significant health and safety concerns can arise during any radiological survey – including the potential industrial hazards commonly found at any construction site. Using the S3 can help to minimize, avoid and even eliminate these potential safety hazards.

The S3 was designed to mitigate dust concerns from its inception. Nearly every portion of the plant is sealed or enclosed to provide positive dust control during operations.

Historians

Multiple software historians constantly record information and allow for simple and accurate preparation of shipping manifests and daily reports.